GPO - Generic Boost Cut Strategy

CM5 and CM5-LT are able implement 3 water methanol safety approaches and take action to cut boost whenever system trouble is detected in order to save the engine from overboost.

The 3 safety approaches are:

Approach 1: Activate one of the two General Purpose Outputs (GPOs) when one the two General Purpose Inputs (GPIs) is activated. This would apply when a fluid level sensor is connected to a GPI triggering it when the fluid level in the tank drops below the float sensor's level.

Approach 2: Activate one of the two GPOs when one of the spare voltage inputs drops below a certain voltage level. This would apply when a water methanol flow sensor with a voltage output is used and connected to one of the two analog voltage inputs (A or B). In this situation the GPO can be activated when the flow drops below a certain user-selected threshold which could mean the pump stopped or the tank ran out of fluid.

Approach 3: Activate one of the two GPOs when the pump current drops below or rises above some user-selected limits. Current that's too high could indicate the line is blocked (due to solenoid failure for example), while current that's too low could indicate the pump is freewheeling because the tank is empty. This mode requires some experimentation from set-up to set-up to dial in the exact threshold values.

These approaches are described in more detail HERE.

When trouble is detected and CM5/CM5-LT activates the configured GPO it's up to the rest of the system to take action in order to cut boost.

Most modern Electronic Boost Controllers (EBCs) have a dedicated "boost cut" or "boost override" input for implementing exactly this type of function. Interfacing the CM5/CM5-LT with such an EBC is described HERE.

However, some EBCs, like the Greddy Profec EBC don't have a dedicated input for cutting or overriding boost. Also, set-ups where factory boost-control is retained will also not have a boost-cut input on the Engine Computer that can just interface with the CM5/CM5-LT's GPO.

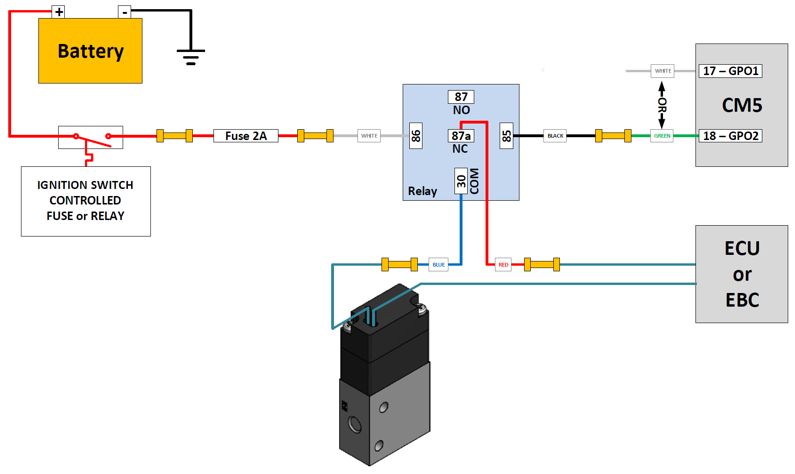

In these cases a different approach can be implemented where a relay is used to break the connection between the EBC (or the Engine Computer) and the boost solenoid. This is accomplished by connecting a relay in-line with one of the boost solenoid wires by using the relay's Normally Closed (NC) and Common (COM) terminals ensuring the boost solenoid and whatever is controlling it are connected by default whenever the relay is OFF. The relay itself is controlled by the appropriate GPO on the CM5/CM5-LT and whener WMI trouble is detected the GPO activates the relay which breaks the flow of current through the boost solenoid and causes it to close. This drops the boost to whatever the wastegate spring is set to with the aim of saving the engine by doing so.

The wiring diagram for this approach is shown here: